Maybe this is one of the more mundane topics, but I believe it is worthy of a dedicated discussion.

When doing a service change, we often are required to “bang in” a ground rod (or two) and connect them to the service. We also need to provide attachment points for landing ground wires by the cable / alarm / satellite guys. Here’s where things get confusing; Local ordinances often modify NEC rules, and trade practices vary considerably.

How do you do the job? I’d like to focus on these details:

-- Do you drive the rods below grade?

— If so, how are the connections inspected?

— What tool is used to drive the rods?

— What wire do you use?

— How do you protect the above-grade portion of the wire?

— Do you bond the wire to the buried end of the conduit? How?

— How do you connect multiple rods together?

— Do you take any steps to protect the wire connecting multiple rods?.

I’m in the middle of a service change, and my practices seem to be unusual around here. I’ve had some trouble finding my usual hardware.

Please post pictures; I plan to do so later this week.

If you are using an 8' rod, it needs to be driven flush to or below ground. (8' of ground contact)

When I was looking, they generally left a little dirt out so I could see it and back filled later. If it was above grade, I loaned them my 2# hammer

I have seen rotary hammers used but here in Florida you could drive it with your Kleins.

#6 solid is all you need but I see #4 used to sidestep the physical protection thing. (Gets back to that "severe" damage thing) They typically bring it above grade next to the building if it is unprotected.

Protection is usually RNC if present.

If it is metal, there is an appropriate fitting that bonds the raceway to the rod clamp. Engineers will tell you high frequency transients will use the raceway and ignore the wire.

Typically the GEC passes through the first clamp and terminates at the second rod clamp unbroken along the way.

RNC or the afore mentioned metal raceway with appropriate fittings if it is not just bare solid, below grade.

Reno

Yes, flush or below grade; some soil left out for inspection

Roto hammer or a small sledge hammer.

#6, stranded, bare, or solid if it's available

Above grade is 3/4" sch 80 PVC, mostly for appearance

No bond/choke required for PVC

Wire is continuous as Greg said, 250.94, to rod to rod

Rod to rod is buried, in PVC or neatly attached to the structure.

Just FYI, I did not do a lot of resi, mostly comm.

I’ve completed the job and hope to soon have pics to post, as an aid to discussion.

The ground was firm, best described as compressed mud. Digging maybe nine feet of 8” deep trench with two 12” pocket holes was a snap.

'

Driving the rods with an SDS-Max roto-hammer was a snap. I’d estimate a total of fifteen minutes for both of them. I was able to start them by pushing the first six inches in by hand. My shiny new roto-hammer runs on a pair of 18V batteries.

I saw an original variation of the pile driver on the internet. Imagine a very big sledge with the handle replaced by a one-inch pipe. By slipping the pipe over the rod, you can hammer the end of the rod without getting on a ladder. Looks to be a great way to start the rod; I might have to make one!

As to burying the wire: I don’t see any depth requirement in the code; applying the usual conductor burial table seems improper. Your thoughts?

About the wire itself: When the requirement for a second ground rod was instituted, a speaker at the local IAEI seminar explained that it was NOT the intent of the code to require a single continuous wire to run from panel to rod to rod. Using one wire to run from the panel to the first rod, and a second wire between rods.I note that NONE of the usual fittings have their terminals oriented to facilitate a continuous wire passing through.

You can easily thread the wire through an acorn before you put it on the first rod. That is usually what I see.

The burial is just to protect the wire from weed eaters and lawn mowers. If you think it needs more protection you can always slip it through some sch 80 RNC.

That "pile driver" idea has been around forever. Fence installers always have one on the truck, usually with 2 big handles.

I used to have a two- handled pile driver. Perhaps I was not clear in describing the variation I saw.

The variation looks a lot like a big sledgehammer. The difference is that the “handle” has been replaced by a length of pipe. The idea is to slip the pipe over the rod, stand the rod up, then push the driver up — only to let it free-fall down the rod. No need to climb a ladder.

Contrast this operation to the usual pile driver, where you carry the tool up the ladder with you, then make your first blows while still on the ladder.

Once the rod is driven most of the way in, you reverse this variation and use it like a tamper (not like a hammer). Again, you’re working while standing, rather than bending over to grab side handles.

Hi John,

It's been a while.

We use this sort of thing over here in New Zealand to protect our earth rods:

Earth Rod Protection BoxPersonally, I've either used an apprentice with a hammer/sledge hammer or a Hilti concrete/impact drill with a large socket on the end.

The worst thing you can have happen when driving an earth stake is have it strike a stone in the ground and have it come up behind you.

That is our soil here.

Foundation grounding is used as a grounding conductor for all metal structures of the building as well as lightning protection. It is known that grounding is required for any building. Foundation grounding is a mandatory requirement for all new construction. The grounding circuit here is embedded in the foundation in order to effectively protect against corrosion. When reinforcing the foundation in our new house, we decided to trust

www.almightyconstructionnw.com because they have a lot of experience with cement and I am not sure that I can do a screed on the floor. Also, they suggested I do the wiring right away and hide everything under the framing that would connect the basement to the kitchen.

The Ufer (concrete encased electrode) is now in our building code too and that eliminates the need for a made electrode like a rod. I have both types of electrode here all bonded together with #2 copper, just because I came up with a bunch from a botched computer room built. I bonded the footer steel on my addition and connected it to the GES. Perhaps my biggest Ufer is an inground concrete pool but you can't say that out loud. NEC purists have their hair catch on fire if you do. Copper doesn't lie tho. There are multiple connections between the MBJ and the pool, mandated by the various code sections referring to grounding and bonding.

Trumpy, that’s a very elegant solution. Alas, the exposed few inches of rod leaves an opening for some jackalope to object that the “entire” rod isn’t in direct earth contact. Conceivably one could do something similar using a “hand hole.” Check zoro.com for the Adamax 910 to see what I’m describing.

Instead, we’re put in a position where we need leave the connections exposed, filling in after inspection.

The “Ufer,” or concrete encased electrode, is a better way in every way. My new garden shed has a length of wire in the slab — just in case I later add power. Alas, there remain millions of homes built before our codes accepted this method. My own 1957 house was “grounded” by the simple expedient of wrapping / tying a small wire around a water pipe.

The service change I just completed was on a house that was first built in 1933, then added to several times over the years and had brick sheathing added. Slab on grade — no crawl space. I don’t think it was grounded at all.

The point is that the humble ground rod is going to be around for many more years.

As I grew up I saw the EGC requirements change, each change making the wire stouter and the protection more robust. Between the lawn mower, the weed-eater, and copper-stealing drug addicts requirements reached the point where installing the EGC became one of the most physically demanding parts of a service change.

Rules now call for:

— Two rods, at least six feet apart;

— The wire can be insulated — any color EXCEPT green,; and,

— We need to provide an exposed connection point for the data guys to land their grounds. For many years this connection point exposed the wire to damage.

This is how they do the Ufer here. Copper thieves made leaving a 4 ga sticking out of the slab a non-starter. They paint that core green so it doesn't get poured solid along with the doweled cells. It gets covered by a 4x4 blank.

![[Linked Image from gfretwell.com]](https://gfretwell.com/electrical/ufer.jpg)

The gec only needs to be continuous to the first rod. Between rods is a jumper under the NEC.

That is technically correct but there are still some crusty old inspectors who say both rods are "the electrode" since you haven't demonstrated one is under 25 ohms. In the practical sense, if they are both installed at the same time, there is no real reason not to loop the conductor through the acorn on the first rod and continue to the second one. Material cost is the same and it doesn't really change the time. It might even be faster. I wouldn't argue either way as long as all the parts are properly listed.

Just an FYI, there are some inspectors that have an issue with the two (2) conductors under the acorn. That is IF the #6 is not a continuous piece. AFAIK the acorn is not listed for multiple conductors.

That said, although we all have come upon a lot of 'conductors' under the acorn, be it telco, cable, dish, etc.

A couple of gripes then I’ll make my point.

First, I’m delighted this thread is starting discussion 😁. That’s what forums are for.

I do wish the board saw greater participation by the folks who actually do the work. They have a different perspective from others, different concerns.

It’s interesting to step back and look at how our views about the ground rod have changed over time. Electrical power has been with us a fairly short time — about 150 years — and, frankly, for the first fifty years nobody really knew what they were doing. This is reflected in the conflicting concepts about grounding.

Why all this fuss about ground rods? Ultimately the ground rod is there only because lightning exists. The ground rod is completely irrelevant to the power company — notice how Norway gets along just fine without them.

Has anyone ever seen an instance where the existence of a ground rod really mattered? Yet look at the minutia in the code on the topic. I can think of no other code section where yesterday’s theories have so often been contradicted by today’s doctrines. But I ramble ….

As to the means of connecting the first ground rod to the second:

— Don’t forget that the two rod requirement has been around only twelve or fifteen years. This means that most service upgrades will require a second rod.

— Acorns are relatively cheap. There’s nothing wrong with using two on a rod ( one for the wire to the panel, another to connect the rods to each other).

— Multiple wires under clamp just seems wrong.

A further general observation about grounding: Got CSST? Let the argument begin!

IMO, when CSST is used in place of iron gas pipe, you need to somehow connect the meter end to the EGC.

I do more service upgrades than new installations. So that usually means I'm pounding two ground rods.

-- Do you drive the rods below grade?

Yes, If I didn't I'd be creating a tripping hazard and violating code for not having 8' of the rod in contact with the soil.

— If so, how are the connections inspected?

I have seen inspectors kick dirt away, but generally the local inspectors know my work and they are more focused on the more critical parts of the install, bonding, etc. I suppose they could require me to dig it back up or leave it exposed.

— What tool is used to drive the rods?

Sledgehammer, sometimes, if the soil is decent they will push in part or some of the way. I do have an adapter for the rotary hammer drill. That is my preferred method.

— What wire do you use?

#6 or #4 solid.

— How do you protect the above-grade portion of the wire?

Generally I try to run it so it is not exposed to physical damage. Occasionally I will sleeve it in sch 80 PVC but usually more for looks than protection.

— Do you bond the wire to the buried end of the conduit? How?

I would never use a metallic wiring method to do this, only sch 80 PVC.

— How do you connect multiple rods together?

I generally loop my wire through my clamps. I have used copper C crimps and added on to existing GECs.

— Do you take any steps to protect the wire connecting multiple rods?

I bury it several inches deep as close to the building as possible.

As to the last post I would never run two wires under one acorn. One or nothing. CSST? The only time I run into an issue there is when I wire furnace change outs in a city inspected area where the electrical inspector also inspects the heating/ gas. He wants me to bond the CSST even though its really not in my scope of work. I feel that if it was suppose to be bonded it should have been done when the building was built. I can either tap on to the GEC to the ground rod outside and run to the fitting on the gas meter, or they allow me to run a #6 from the water main or main service panel to the indoor gas manifold. Usually its the second choice. Since its not a GEC or part of the electrical system, they are fine with mechanical means rather than an irreversible connection.

Just an FYI, there are some inspectors that have an issue with the two (2) conductors under the acorn. That is IF the #6 is not a continuous piece. AFAIK the acorn is not listed for multiple conductors.

That said, although we all have come upon a lot of 'conductors' under the acorn, be it telco, cable, dish, etc.

Nope. One per acorn. Go to your truck and get another one for another wire. That is why I said it is probably cheaper to just loop the wire through. That is the same as trying to get 2 wires in a breaker with a single wire lug. One of them is not getting proper clamp pressure. There are clamp type connectors that are listed for multiple wires (multiple holes) but a lot of them are not listed for burial.

I will disagree about the need for a good grounding electrode. Yes lightning and surge protection requires a good ground reference that everyone uses (PoCo, Cable, Telco, Satellite).

There is also a safety issue. If you are counting on the PoCo ground for a reference in wye distribution, expect to see several volts between their neutral and the actual dirt under your house, concrete floors, water pipes etc. It was enough to wake me up when I first moved here. Everything "grounded" would give you more than a tingle if you were barefoot on the terrazzo floor. I found the ground clamp, not listed for burial, had rusted off (bolts failed). I had some bronze ones in my truck from doing raised floor bonding and a new clamp fixed the problem but it did point out the value of the ground electrode. I grew up with copper service pipe going to cast iron that went everywhere so we always had a good ground. In fact you could lift the neutral and usually nobody would ever know. You were using your neighbor's neutral.

I did a study some years ago about how much stray current there is is my single wire wye distribution here. There are a few amps on my neutral with the main breaker off, coming from the utility and the pole ground wires run from less than 1 to over 3 amps.

You can talk theory all day long but Dr Ohm always wins. The voltage drop in the utility neutral shows up as a voltage rise on your neutral and that 4 gauge wire stapled to the bottom of the pole and going up to the transformer is no match for the current imposed on it. That is their ground electrode.

I remember a number of years ago doing some plumbing work at my grandmas house- I was replacing a section of galvanized pipe with copper. I had remove the clamp for the GEC. (When that service was installed it was still up to code to connect near the panel and rely on the piping as long as you still had the meter jumped out). I put my clamp on ammeter and it was drawing 10 amps. It did draw an arc when I disconnected it, but checking with a dmm, there was no difference in potential. That told me that one of the neighbors neutrals is probably compromised. Much more recent we were connecting a new GEC to the water main for a 600A service upgrade in a downtown building, and witnessed quite a bit of arcing upon disconnection of the old GEC. Still no difference in voltage.

One should really tread lightly in these instances, some or most of that current could be the utilities neutral current due to parallel paths and marginal connections.

Those utility neutral imbalance stories all seem to involve water pipes carrying current between houses because of a failed neutral at one house.

Voltage gradient stories seem to all involve a utility trying to use Mother Earth as a deliberate neutral return path, or an industrial facility with an ungrounded distribution network. Amazing how hard folks try to eliminate one wire!

Ground rods, by comparison, aren’t there for anything but lightning. Look at where they’re required — each discrete target gets rods.

Ever wonder about where the six foot spacing or eight foot length comes from? The American Electrician’s Handbook has the data. Those are the approximate points where greater spacing or longer rods show “diminishing returns:” increases show very little improvement.

Look at it this way: electricity wants to “go home” to the transformer where it originated. The only electricity that originates in the earth is static electricity— which is primarily lightning.

That mile long 2 ga neutral on the pole is not going to carry all the neutral current from the primary so some of it is going through the ground no matter what. I suppose if they used delta distribution it wouldn't be an issue but they don't. I did see delta where the transformers were L/L in Maryland but never here. They had all three primary phases on the pole. Here it is one phase and a neutral.

https://gfretwell.com/electrical/Transformer%20connections.jpg

I have a question, existing building has a 3-wire 1Ø feeder, which was allowed when installed, a new structure was built 29 years ago that was attached to the existing structure & a Ufer was installed in the new building but never used since the existing disconnects were left alone, fast forward almost 20 years & the original part of the building was razed in order to get proper footings & a concrete floor, a Ufer was also installed, when he existing equipment was reinstalled on the new structure, would both Ufers be required to be used? There was only a few feet between both rebar stubs so they were tied together, and it's still a 3-wire feeder, although that will change that is a advantage having a oversized UG conduit.

If the 2 Ufers were tied together in a compliant fashion, either a 30" lap for #5 (48x) or a 4ga jumper they are being used together. I would say if it was easy (AKA "available") they both need to be used but I wouldn't go to war over it..

Here are the rules, as I understand them:

— Each lightning target requires a ground rod ( or electrode). Exception: One multi wire branch circuit (or less) needs no such electrode;

— All grounding electrodes need to be connected into the same network; and,

— These connections may be “indirect;” that is, by using the ground wire in feeder circuits.

Some examples:

— A house with a detached garage. If the garage has but one MWBC, no grounding electrode is needed. When there is a grounding electrode, you can bond that electrode to the sub-panel you have in the garage. The green wire between the sub-panel and the house panel will suffice to “connect” the electrodes into the same network;

— The cable guy drives in a little rod of his own. You need to connect his rod to yours. You can do this directly (by running a wire from his gear to the inter system connection block) or indirectly by landing his wire on the ground buss of any convenient panel; and,

— For whatever reason, you install your two rods to opposite sides of the service. You can either run your GEC from the panel to rod #1 and then on to rod #2, or you can run separate GEC’s to the ground buss of the panel.

If the 2 Ufers were tied together in a compliant fashion, either a 30" lap for #5 (48x) or a 4ga jumper they are being used together. I would say if it was easy (AKA "available") they both need to be used but I wouldn't go to war over it..

The rebar stubs up a few feet away from each other, there is a continuous piece of bare copper connecting both stubs to the main disconnect, there is no overlap between the rebar in each footing as one was poured in 1993, & the other in 2011, the Ufer in the 1993 build was never used as the panels had a ground rod as the electrode & nothing was changed then, but decided to have the Ufer since the steel was being put in the footings.

That is what the code means when it says "available". The 1993 Ufer probably should have been used all along. There is some debate about whether a stub up is a legal connection but it is pretty much universally accepted here. There have been cases where contractors had to chip up concrete to connect a Ufer. The steel in the foundation is code here.

Interesting scenario, NorCal.

Using my model of “one lightning target, one ground electrode,” you NEED use only one.

When Mr. Ufer invented his electrode, his goal was to ensure excellent contact between the electrode and Mother Earth. A wire within poured concrete set upon the ground provides as good contact as you’re ever likely to have.

What hasn’t been foreseen is the possibility of a building having a split foundation— which is what you describe. Trade practices would have the foundations solidly connected to each other, but those connections would not involve bonding the rebar together.

Now, for the sake of discussion, let’s consider an industrial building with an ungrounded service (no neutral). Such buildings typically have excessive bonding of the building steel and machinery to the ground electrode. This is one scenario where having such a split foundation might result in some unusual electrical problems.

Another possibility is someone later bonding to the unused Ufer. That would violate the requirement that all grounding electrodes be bonded together, possibly creating a potential difference between parts of the same building.

So, while code doesn’t explicitly require both Ufers be connected, I would consider such to be good practice.

I can't believe that them rebar sections in that trench that form an Earthing/Grounding system aren't welded together with an Arc Welder, over here, that would fail an inspection.

Trumpy, that’s a very elegant solution. Alas, the exposed few inches of rod leaves an opening for some jackalope to object that the “entire” rod isn’t in direct earth contact.

That rod that you see, is the end of 3 x 6' rods welded together to effect a 0.15 ohm return path.

I welded some rebar in a couple of my projects and the concrete guys were amazed both times. Typically steel is "continuous" if it is lapped 48x the diameter of the rod and tied with wire. In a Ufer the concrete is considered a conductor

Greg,

I used to do a lot of work in wiring dairy sheds (parlors I believe you guys call them over there).

Cows cause a real mess if there is ANY stray voltage due to poor earthing.

The standard used to be that you had to have a maximum earth resistance of 0.05 ohms at any point to earth.

Everything was multiply bonded, it was a nightmare, I don't miss them days.

Although it did make me buy one of them Fluke multi-function testers, best (lots of) money I ever spent.

Grounding together with the leakage relay in an electrical installation is our basic protection. A good ground such as the foundation (ground) absorbs all the electrical leakages (electrical currents) that will occur in an installation, from a fault. In short, the role of grounding is to transfer to the ground (the earth), the dangerous electrical leaks that can cause electric shocks to humans. The installation of foundation grounding imposes a prefectural basis not only in Patras but throughout Greece, in all new buildings.

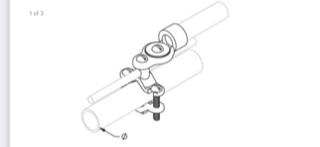

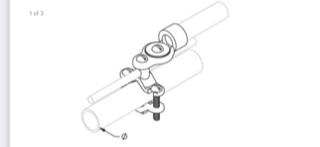

This tool looks interesting — it lets your demo hammer grip the rod closer to the ground. Much less of your impact is lost to the rod wobbling, and no need to start from a ladder.

Has anyone tried it?

Description: Rod driver

I was really hoping someone had tried that rod driving accessory. For this job I had bought one -- and promptly lost it

No matter; both rods went into clay readily using an SDS-Max demo hammer.

Now: for the ground wire ("GEC", or Grounding Electrode Conductor). It has been my practice to run a #4 solid wire in EMT to the first ground rod. Since this particular location would have made the pipe a trip hazard and annoying to the gardener, I chose to use heavier pipe (RMC).

Starting at the panel, I used an intersystem grounding bonding device sold by Ideal. This device connected my pipe to the panel and completely protected the wire. The Phillips screw, when tightened, bonds the wire to the inside of the block. This is the only intersystem bonding device I've seen of which I approve. (first picture)

(I'll post additional pictures separately. I wish to encourage discussion on each detail of this job).

As for the EGC, and the manner of its protection: Growing up in the Sixties, I saw the grounding practices change quite a bit.

Before 1960, IF there was a ground at all, it was a light gauge wire that was tied off to a water pipe.

Once ground rods became typical, I often saw an unprotected wire go to a rod that was often either inside the crawlspace or punched through the basement floor.

In the suburbs, with the surge in "ranch" style tract homes, requirements quickly evolved. First the lawn mower, then the weed whacker were blamed for damaging the wire. This led to requiring (first) solid wire, then upping the size to #4, then requiring the wire to be in pipe. By 1970 the use of EMT was universal -- the use of PVC, even today, is greatly discouraged. (Think: Chicago)

In Arkansas today, a typical EGC will be #6 stranded (usually green -- forget the NEC!) in PVC. About a foot fron the panel the PVC will be separated and a surface-mounted intersystem bonding block inserted.

For this job I chose RMC, bent to protect the wi

re until it was well underground. I protected the pipe from corrosion with heavy vinyl "pipe wrap tape".

Description: Wrapped pipe

Now, about bonding the GEC to the conduit . . .

Some have expressed fears that should the GEC not be connected to the conduit at BOTH ends, a "choke" can occur that will reduce the current carrying ability of the wire. Personally, I think this is a non-issue. I defy you to run a bare #4 wire through bent pipe without the wire contacting the pipe at several points.

None the less, a connector is made for this task. I've used them several times, and I've attached a catalog drawing of one. Alas, electrical supply houses here have exactly zero interest in obtaining them. Indeed, they look at me as though I'm out of my mind for wanting such a thing. ("I've been in this business forty years and never had anyone ask ...")

Time waits for no one, so I had to improvise. I've attached a picture; combine a rigid coupling with an NM 2-screw connector and you get something that just might work. Picture attached.

Description: Connector Drawing

Description: Field expedient connection

That must be a northern thing. I got one here with no problem and as an inspector I saw them all the time. As for the Romex connector, I would cite 110.3(B) and tell you to come up with a better solution. They are not listed for direct burial and that strap will rust out in less than a year.

How long do you think those steel ground screws will last in the weather? Do they sell a 3r enclosure for that ground block? I like the idea but the weather protection seems weak. The blocks I see here usually have a plastic box with a cover that snaps shut. If they don't use a little duct seal the wasps love them tho.

Reno,

The protection of the GEC up here (resi) is PVC for 'physical protection and 'neatness'. Comm jobs are usually direct burial under the concrete and the rods are 'flush' to grade in the adjacent soil. The terminations of the GEC to the rods is down 6"+ from the top of the rod, so the conductor is 'safe'.

The larger comm jobs usually are spec'd for 10' rods in triad, with inspection holes at each rod for testing purposes, so damage is not a question.

As to the 250.94 blok, I like the design, but as Greg said, corrosion issues; however, at time of inspection it should NOT be an issue. (Possible firestorm comment)

The 2 screw NM connector is and has been an 'issue' item around these parts for many, many years. Personally, I can't see it for choking purposes on metalic conduits with GEC conductors. (Inside)

And FWIW, you really do address the details.

Interesting you mentioned "inspection". EC&M Magazine has a grounding article on the cover. They go through and list all the legal connectors you can use for grounding and Romex connectors do not make the list. 110.3(B) seems to be enough but you could go to the language cited in the article if you want more.

OTOH if someone did come up with bronze or stainless strap and screws for that zinc NM connector body I might chuckle and walk by. I also might agree with Reno that a short sleeve on a direct buried copper wire won't be much of a choke anyway and just ignore the whole thing.

t really doesn't come up here either. They like RNC.

I used the hubs and EMT at my house, just because Home Depot had the part.

One of the crazy McIver setups I came upon was 3/4" EMT, compression connector, 3/4" pipe coupling, and a "Kenny Clamp" for a choke/bond. 110.3(b)?? I had a good laugh. The cost overruled the purpose.

He said, "I could use PVC???"

I want to, again, thank everyone for their participation -- and your kind words!

With my threads it's not my purpose to preach or to brag. I post these topics as a way to invite discussion. Far to many forums stifle intelligent, respectful discussion, with comments too often limited to either "Here's how it's done" or "the code says . . . " Far too many comments sound, to my ears, like they come from an easy chair that has never seen a rainy day in the mud of a job site.

Let's look at the "official" connector and its use in more detail:

-- As mentioned, supply houses in the Mid-South have been unable, or unwilling, to obtain them. I just didn't have time for an internet order. While PVC might have worked, a look at routing of the pipe suggested to me that the exposed PVC would not survive long. I wasn't willing to either cut up the concrete slab or speculate as to the location of the foundation footings.

-- The "official" fitting is sized for 1/2" pipe. Only today, looing deep into the catalog, did I learn it's also made with a 3/4" hub. Ever try pushing #4 solid through bent pipe? I bet you quickly decide to violate the code requirement to "complete the pipe THEN pull in the wire, and instead put the wire in the straight pipe and bend it later!

-- Again, looking at the spec sheet, I discover bothersome detail: the connector with the 1/2" hub is designed for wire no larger than #6 solid. Well, that might explain some of the troubles I've had mounting #4! As designed, the wire is supposed to go under a brass fender washer and wrap around a screw, coming to rest in a nice circular groove. The only way I've been able to do that with #4 is to heat the wire with a torch, bend it, then trim off the tail. Then I find it necessary to replace the provided screw with a slightly longer one and re-assemble.

-- Note that the "official" connector comes with zinc plated steel screws. The spec sheet makes no reference to direct burial.

-- As a final note, the "official" connector does not lend itself to having the wire pass through and on to a second rod. (Erico, are you listening?)

Description: RNC Ground

Reno,

I have to ask, why do you use #4 solid to the rods ??

You mean there are other choices? 😁.

Use of #4 solid has been mandated by local standards since the early Seventies— at least in Chicago and Reno. Even here (Memphis, Arkansas, and the Missouri boot heel) the use is routine. It was one of the few things about my service change that didn’t surprise the local suppliers.

Even though the NEC is quite clear that a GEC need not be larger than #6, and is silent regarding solid or stranded, local rules are common. Let’s review how we got here.

The first homes to have any manner of grounding often had a small (#10) wire connected to a water pipe. By the early Sixties the addition of a ground rod had become common, still using a small wire.

As Americans moved to the suburbs, these wires came into conflict with lawnmowers. This led to locales asking for ever larger wires, until #4 solid was accepted as “tough enough.”

Then came the weed hacker — and, by the late Seventies, a sharp rise in copper prices. Various surveys and inspections revealed the ground wires were either damaged or missing. Thus, protecting the wire with conduit became the norm. Living outside Chicago at the time, PVC was never an option.

I've attached two pictures of the most common GEC install in this area.

I believe the intersystem ground buss is what HotLine described earlier. I don't like the way it interrupts the conduit and eposes the wire. That's why I much prefer the way the Ideal fitting connects to the panel as well as the pipe. I'm not worried about the connections to the data/phone/etc. grounds being exposed; those wires are usually just stapled to the siding.

In a similar manner, the GEC is exposed at the connection to the ground rod. Again, I don't lie the way the conduit is left dangling. Had I been able to get the proper fitting, I would have run the pipe all the way to the rod. (At least the exposed wire will be buried and out of site).

Finally, note #4 solid is used.

I see the EGC coming into the meter can. Do you land it there or take it to the service disconnect enclosure?

The 4ga thing came from older cycles of the code when 250.64(B) said

(B) Securing and Protection Against Physical Damage.

Where exposed, a grounding electrode conductor or its en-

closure shall be securely fastened to the surface on which it

is carried. A 4 AWG or larger copper or aluminum ground-

ing electrode conductor shall be protected where exposed to

physical damage. A 6 AWG grounding electrode conductor

that is free from exposure to physical damage shall be per-

mitted to be run along the surface of the building construc-

tion without metal covering or protection where it is se-

curely fastened to the construction; otherwise, it shall be in

rigid metal conduit, intermediate metal conduit, rigid non-

metallic conduit, electrical metallic tubing, or cable armor.

Grounding electrode conductors smaller than 6 AWG shall be

in rigid metal conduit, intermediate metal conduit, rigid non-

metallic conduit, electrical metallic tubing, or cable armor (from 2008)

Although they didn't explicitly say 4ga did not need protection, that was the way it was read unless it was subject to physical damage, whatever that means.

Solid was seen as being tougher than stranded.

It really got down to what the inspector expected to see.

The reference to 4ga went away in 2017

(B) Securing and Protection Against Physical Damage. Where

exposed, a grounding electrode conductor or its enclosure

shall be securely fastened to the surface on which it is carried.

Grounding electrode conductors shall be permitted to be

installed on or through framing members.

(1) Not Exposed to Physical Damage. A 6 AWG or larger

copper or aluminum grounding electrode conductor not

exposed to physical damage shall be permitted to be run along

the surface of the building construction without metal covering

or protection.

(2) Exposed to Physical Damage. A 6 AWG or larger copper

or aluminum grounding electrode conductor exposed to physi‐

cal damage shall be protected in rigid metal conduit (RMC),

intermediate metal conduit (IMC), rigid polyvinyl chloride

conduit (PVC), reinforced thermosetting resin conduit Type

XW (RTRC-XW), electrical metallic tubing (EMT), or cable

armor.

(3) Smaller Than 6 AWG. Grounding electrode conductors

smaller than 6 AWG shall be protected in RMC, IMC, PVC,

RTRC-XW, EMT, or cable armor.

Greg, I didn’t do the job with the PVC conduit, so I don’t know what was done.

As for my job, the panel had both the disconnect and the meter base, so I simply landed the GEC on the ground buss.

When I installed a bank of meters for an RV park (individual meter bases), I landed that GEC in the disconnect. IIRC, the meter socket neutrals were factory bonded to the enclosures.

Yup, that has been the issue here. It was becoming standard to land the EGC in the meter can. Then the debate got started that you now had a parallel neutral if the nipple through the wall was metal. They did massage the language in Article 250 a little in regard to "service equipment" but we still had some old timers who thought it was wrong. As far as I was concerned, I really didn't care about things that happened on the line side of the MBJ. That was the place where we worried about neutral and ground going off on their own path, never to meet again.

Okay, now I see where this is going . . .

I once got an emergency “power out” call from a major industrial customer on Thanksgiving. Seems their computers were down and there were some crazy power quality issues. The cause turned out to be degraded bonding between panels.

In this particular place — which had been built by the very guy who got the Ufer into the code — the main service had mounted right next to it three large panels, all connected together by RMC nipples. In each panel the ground buss was bonded to the neutral buss. For the brief space between the panels and the main disconnect, the pipe was acting as both neutral and ground, just carrying the current imbalance. Loosening and corrosion, over time, had made this a path with great impedance. Separating the grounds from the neutrals and extending the neutral from the panels back to the main disco solved the problem.

That’s where this discussion is getting off track. We are NOT talking about (fault) ground paths here. We are talking about the GEC — a wire that some modern countries don’t even use. The GEC if of relevance only for “natural” electricity — that is, static and lightning. That’s the only electricity that has any interest in going to earth. PoCo power wants to go back to the PoCo transformer where it was made.

The idea is: Each lightning target gets one GEC network. For an example like the PVC service pictured (meter base serving a disconnect right next to it, on the same structure), I would say the preferred practice would be to run the GEC to the meter base rather than the panel. After all, lightning will hit the meter can first . . .

The argument was about neutral current flowing through the metal nipple behind the panel to the meter can. They did not want to admit, that happens no matter what if you have a metal raceway and a bonded ground to neutral in the meter base.

These are the same guys who won't admit an inground concrete pool is an electrode, the biggest Ufer in the system.

The EGC and the bonding grid get bonded all over that system. (Pumps, lights, pool covers, heaters etc) and they are all at least 12ga wire. That is a lot of copper that electrons can flow through.

I went ahead and drive rods at the AC compressors and sat dishes, connected to the grounding system with 2ga (I had a bunch) I figure a big equipotential grid around my whole house should help with the surge protection. Then I stack layers of protectors on that.

Here in NJ, one POCO does NOT allow the GEC to be terminated in the meter base, or pass thru the base. Another POCO allows termination at the neutral within the meter base. There are two other POCOs that I am not familiar with.

The towns I inspect in are all in the "No GEC in the meter base"; on occasion we see a EC from the southern part of the State, and we know where he's from by the GEC terminated in the meter base.

HotLine, you caught me in a major mis- speak. Probably best to bleep out my earlier comments about running the GEC in the meter base and explain what I was really thinking about before I had a senior moment.

My typical service change does not have separate base, disconnect, and overload components. All three are contained in the same “all in one” panel. In these panels you land the GEC to the ground bus. A factory installed bar bonds the neutral buss to the ground buss.

The “other” way — and here is where I got confused — is done where you have several services supplied by one service drop. Imagine an apartment building or RV park. Here there is a main disconnect before the meters. When all these services are in the same building, the GEC lands in the main disconnect. When the meters serve different structures there are additional ground rods at each structure, with those GEC’s landing on the ground buss.

When I have separate structures, I maintain separation of the neutrals from the grounds from individual disconnect at each meter. That’s the only place where the grounds and neutrals bond.

I apologize for my confused answer above.

Reno,

I'm a guy with senior moments also, so no problem.

Here, 'all-in-ones' do not exist. Common for a SFD is riser to meter pan, to panel, or to a main disco IF the panel is not behind or directly in the basement. (Let's not go there with the "distance")

Multi-family use meter stacks. and over six they have a main disco.

Now, with the 2020 requirement of the 'emergency switch' on the exterior, there will be a 'main' after the meter.

With the current materials issues, that has been a problem. Our POCO has yet to approve a meter/main combo unit.

BTW, Thank you for generating a thread that generated some debate.

The first place we saw meter/mains was in piling houses so they could have a disconnect at grade and it also made it easy to retrofit living space under the house in the flood zone after the CO. Ian has a lot of folks considering the wisdom of that decision after FEMA denied all claims for things below the permitted finished floor.

Meter mains are also the most common way to do a service upgrade. They typically leave the existing panel, rewired as a sub and then add new loads to another sub. I was just over at a neighbor's house looking over his plan to do an upgrade and define the scope of work he needs to contract. For him, it is actually fairly easy. His grounds and neutrals are already on separate buses in the main so he only has to lift the MBJ in the existing and pull in a new EGC. (back to back install) He may get away with only a few hours of billable time to swap out the existing meter can with an all in one. His plan is to add another 50a for the RV he is living in now because of the flood and for his new Tesla when he gets it. I am not willing to bet which will come first. The meter main he has picked out has a bunch of slots so he will have plenty of growing room. I imagine 320a is probably all FPL will give him but that should be plenty. I am curious if they even swap out the 2 ga aluminum drop. They are real bad about that. One of my other friends had to fight to get a heavier drop, They said they doubt he was ever even going to stress the drop he had.

Greg,

Are the bits of rebar that form that system actually welded together with a stick welder along it's length or does it merely expect that the contact between the rods with tie wires "is enough" to carry fault currents after the concrete has been poured over it?

The concrete itself is the conductor. Rebar is lapped and ties for 48x the diameter to be considered "continuous" and it is felt that the physical contact and the concrete itself is enough to establish a ground reference for the grounding electrode system. Fault current itself is send back to the utility via the bonded neutral, not the GES. The GES is really only there to establish a ground reference and mitigate transients, not fault current.

250.4(A)(A) Grounded Systems.

(1) Electrical System Grounding. Electrical systems that

are grounded shall be connected to earth in a manner that

will limit the voltage imposed by lightning, line surges, or

unintentional contact with higher-voltage lines and that will

stabilize the voltage to earth during normal operation.

![[Linked Image from gfretwell.com]](https://gfretwell.com/electrical/ufer.jpg)